Welcome to the PAC Global Leadership Awards Innovation Trends update brought to you in partnership with UK packaging innovation consultancy, ThePackHub. We have hand selected five packaging innovation highlights that we think are deserving of mention and will pique your interest. Look for more of these in the coming weeks!

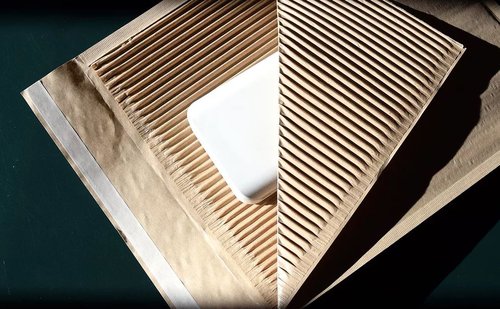

A new plastic-free alternative for e-commerce envelope mailings has been introduced. The WaveBag solution uses a proprietary wave padding to protect the contents. Instead of using PE-based air bubble wrap, the Wave Bag envelopes have an inner protective layer consisting of paper ‘waves’ to give the necessary rigidity and strength. Internal drop and resistance tests have shown that WaveBag is able to better maintain protection compared to a bubble mailer where the bubble starts to deplete causing a loss of protection. Wave bag is 100% paper-based making it fully recyclable. It is claimed that it can reduce CO2 footprint and transport costs of more than 50% with an additional reduction of 47% in storage space. There are 10 different sizes available.

A new plastic-free alternative for e-commerce envelope mailings has been introduced. The WaveBag solution uses a proprietary wave padding to protect the contents. Instead of using PE-based air bubble wrap, the Wave Bag envelopes have an inner protective layer consisting of paper ‘waves’ to give the necessary rigidity and strength. Internal drop and resistance tests have shown that WaveBag is able to better maintain protection compared to a bubble mailer where the bubble starts to deplete causing a loss of protection. Wave bag is 100% paper-based making it fully recyclable. It is claimed that it can reduce CO2 footprint and transport costs of more than 50% with an additional reduction of 47% in storage space. There are 10 different sizes available.

It is not always easy to create a point of differentiation through packaging in the beverage industry and the task in hand is increasingly sustainability based. Carlsberg have undertaken several environmentally-focused initiatives over the last few months. They have a different focus for their latest innovation which aims to improve the longevity of their products with a new initiative via their bottle cap. Carlsberg’s view is that ‘fresher beer equals better beer’. Their Fresh Cap innovation has been designed to reduce oxidation via an oxygen scavenger inside the liner of the cap. This results in less oxygen in the bottle actively absorbs oxygen, removing it from the head space in the bottle. The reduction of flavour oxidation ensures that the beer that tastes fresher for longer. The solution promises up to a 15% longer freshness period compared to other conventional caps on the market.

It is not always easy to create a point of differentiation through packaging in the beverage industry and the task in hand is increasingly sustainability based. Carlsberg have undertaken several environmentally-focused initiatives over the last few months. They have a different focus for their latest innovation which aims to improve the longevity of their products with a new initiative via their bottle cap. Carlsberg’s view is that ‘fresher beer equals better beer’. Their Fresh Cap innovation has been designed to reduce oxidation via an oxygen scavenger inside the liner of the cap. This results in less oxygen in the bottle actively absorbs oxygen, removing it from the head space in the bottle. The reduction of flavour oxidation ensures that the beer that tastes fresher for longer. The solution promises up to a 15% longer freshness period compared to other conventional caps on the market.

August Faller are a German manufacturer and supplier of pharmaceutical packaging headquartered in Baden-Württemberg, Germany. The business has developed a new three-layer label that has excellent practical medicinal applications. Their new DryPeel Flag label has been designed to be removed easily in layers. No residue or adhesive is left behind. The labels have been designed so that they adhere to the container and stand out like a flag. It is suitable for documentation and product marking for medical practitioners to record product usage. The middle layer is easy to separate from the base label. More label parts can also be removed for necessary medical descriptions and comments. The user can mark the labels easily with a pen. A transparent base label ensures that the main pack is not visually compromised.

August Faller are a German manufacturer and supplier of pharmaceutical packaging headquartered in Baden-Württemberg, Germany. The business has developed a new three-layer label that has excellent practical medicinal applications. Their new DryPeel Flag label has been designed to be removed easily in layers. No residue or adhesive is left behind. The labels have been designed so that they adhere to the container and stand out like a flag. It is suitable for documentation and product marking for medical practitioners to record product usage. The middle layer is easy to separate from the base label. More label parts can also be removed for necessary medical descriptions and comments. The user can mark the labels easily with a pen. A transparent base label ensures that the main pack is not visually compromised.

Cohda is a product design, development and research studio based in the North East of England. The business has been working on a development to help consumers better identify waste packaging materials. There remains a lot of confusion about what can and cannot be recycled with similar looking packs often having different recycling rules and on-pack guidance is not always completely clear. The business has developed near-infrared spectroscopy technology that incorporates a unique ‘digital fingerprint’. Cohda have developed a R.I.D (Recycling Identifying Device) concept. The handheld device uses NIR to identify recyclable and non-recyclable materials. Materials absorb varying wavelengths when encountering NIR radiation. Different bonds within the material absorb varying wavelengths giving the material a unique absorption pattern. There is a stored database of these digital fingerprints that can be updated as and when new product lines enter the market.

Cohda is a product design, development and research studio based in the North East of England. The business has been working on a development to help consumers better identify waste packaging materials. There remains a lot of confusion about what can and cannot be recycled with similar looking packs often having different recycling rules and on-pack guidance is not always completely clear. The business has developed near-infrared spectroscopy technology that incorporates a unique ‘digital fingerprint’. Cohda have developed a R.I.D (Recycling Identifying Device) concept. The handheld device uses NIR to identify recyclable and non-recyclable materials. Materials absorb varying wavelengths when encountering NIR radiation. Different bonds within the material absorb varying wavelengths giving the material a unique absorption pattern. There is a stored database of these digital fingerprints that can be updated as and when new product lines enter the market.

Skinny Tonic is a UK-based Indian tonic water from Double Dutch brands. The business has responded to pressure to remove plastic with the switch from plastic shrink wrap into cardboard. The new boxes have clear messaging to on the packs to ensure that the boxes are removed before being displayed. Using a paper-based material, the new solution is overtly more environmentally-friendly and easier to recycle. The business concedes that it would have been a lot easier and less expensive to use plastic shrink wrap to deliver the product. The solution reduces operational energy consumption as a shrink tunnel is no longer required.

Skinny Tonic is a UK-based Indian tonic water from Double Dutch brands. The business has responded to pressure to remove plastic with the switch from plastic shrink wrap into cardboard. The new boxes have clear messaging to on the packs to ensure that the boxes are removed before being displayed. Using a paper-based material, the new solution is overtly more environmentally-friendly and easier to recycle. The business concedes that it would have been a lot easier and less expensive to use plastic shrink wrap to deliver the product. The solution reduces operational energy consumption as a shrink tunnel is no longer required.

These innovations are a selection of nearly 3,500 uploaded to ThePackHub’s Innovation Zone database. If you like to know more about a subscription, please let us know.